IN-SERVICE SUPPORT - Gastops Ltd.

BY MARC MONTGOMERY

Detect Prevent Preserve

Whether a military asset or your own body, early problem detection is key to rectifying the issue before it becomes serious. For our bodies, regular medical blood tests can reveal if there is a health issue. But what if you could get accurate health data weekly, daily, or even in real-time to detect issues between widely-spaced scheduled checkups?

Whether a military asset or your own body, early problem detection is key to rectifying the issue before it becomes serious. For our bodies, regular medical blood tests can reveal if there is a health issue. But what if you could get accurate health data weekly, daily, or even in real-time to detect issues between widely-spaced scheduled checkups?

What if you could get accurate up-to-date information on the 'health' of equipment? In a sense, lubricating oils might be considered the 'blood' of engines and transmissions and can certainly reveal internal component condition. Through state-of-the-art technologies developed by a Canadian company, engine and gearbox fluids are now revealing up-to date machinery health information on the world's most advanced aircraft. These technologies have proven their pedigree in the aviation space, with the company focusing on expanding their presence in the naval marine and land vehicle space.

Gastops Ltd., whose name is derived from Gas Turbines and Other Propulsion Systems, has been working with DND/CAF for some 44 years with its world-leading equipment health diagnostic and prognostic measurement and analysis technologies. Formed in 1979, Gastops began as an engineering firm working primarily with the aerospace industry, pioneering in computer digital-twin modeling of gas turbine performance and potential failures.

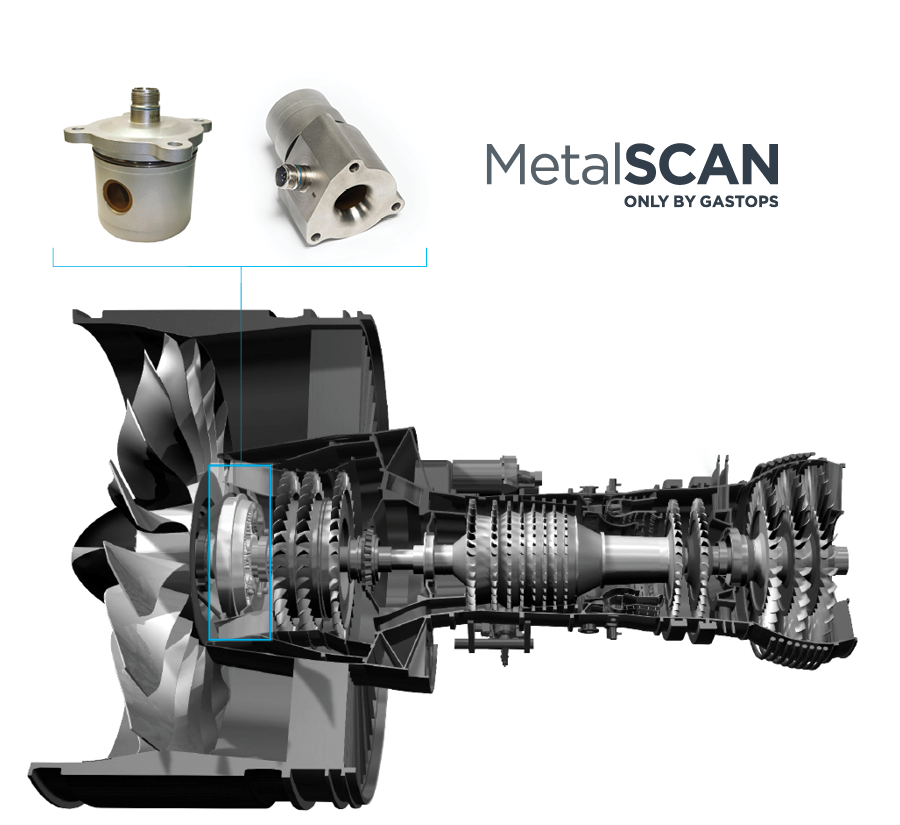

Today, the company’s products, MetalSCAN and ChipCHECK, are being used by Allied militaries around the world in today's most sophisticated platforms including the F-22, F-35, Eurofighter Typhoon, and aircraft powered by Pratt & Whitney’s Geared Turbofan engine. These products are designed, manufactured, and supported from its headquarters in Ottawa and positions Canada as a world leader in diagnostic and prognostic technologies. With some 230 employees, Gastops now has offices in Halifax N.S, and Mount Pearl, NL, and a U.S. affiliate which services the U.S. DoD.

Due to their ability to distinguish early wear and detect component failure, Gastops’ products are becoming standard in saving assets from severe operational damage thereby reducing maintenance burdens, improving availability and keeping critical assets mission-ready for longer to meet operational needs and objectives.

"We develop disruptive technologies to address the most pervasive issues associated with equipment maintenance and availability,” said Brennan West, Director – Defence and Aftermarket Business. “We study how equipment operates, how it fails and develop groundbreaking technologies to support our partners and customers," he told CDR.

EFFICIENT MAINTENANCE

To prevent asset damage and potential failures, schedule-based Preventative Maintenance (PM) was developed ages ago. Based on calendar or operational-hour intervals, engines and rotary-aircraft transmissions are taken out of service for such things as lubricant and filter changes, and visual and functional verification of other components. Typically, following a set number of preventative maintenance cycles, the unit is removed for a complete overhaul. This has worked well in preventing serious damage and failures, but it is costly and puts a strain on both operational needs and limited maintenance resources.

While on one hand Gastops technologies can capture and diagnose early problems through continuous accurate monitoring between scheduled maintenance, they can support transition of PM tasks such as magnetic plug inspections and oil samples to move towards condition-based maintenance (CBM) through precise analysis of the lubricants for indications of internal component wear.

MetalSCAN, an inline flow-through technology about the size of a computer mouse, is either fitted onboard by an OEM or retrofitted. It constantly measures 100% of microscopic metal particles in the lubricant, thus indicating if there is unusual wear on internal components of an engine or gearbox. In aviation, analysis results are reviewed post flight by maintenance engineers. In marine or land-based use, real time data is provided for diagnosing unit condition and/or providing prognostics of continued safe operation of the unit without damage or propulsion loss. The value of this technology is demonstrated by the more than 40,000 units in service with military and commercial operators globally.

In conjunction with MetalSCAN, another unique world-leading technology is ChipCHECK. This technology can quickly and accurately identify the metallurgy of particles to help determine their component origin within an engine or transmission. Only Scanning Electron Microscopes (SEM) provide similar analysis, but this requires sending samples away where highly trained technicians are required to operate the microscope. This process is costly and increases delays and asset downtime. ChipCHECK is easily integrated into a hangar or aboard a ship, and an operator can be trained in roughly an hour to provide unambiguous results in real time to support airworthiness decisions.

METALSCAN, CHIPCHECK & OCCM

DND/CAF has launched the ‘All Systems Go’ challenge to industry which according to a government website is "seeking innovative solutions for fleet-wide, automated, proactive Health and Usage Monitoring Systems (HUMS) for military platforms. The goal is to support a movement to Condition-Based Maintenance (CBM), and ultimately, predictive maintenance, to optimize limited maintenance resources, and to increase the availability of operational platforms".

While MetalSCAN and ChipCHECK are already key innovations towards achieving these targets, Gastops has obtained funding from the forward-looking Innovation for Defence Excellence and Security (IDEaS) program to push its latest revolutionary Oil Condition and Contamination Monitoring (OCCM) concept from Technology Readiness Level-3 to TRL-7.

The rationale behind OCCM is simple - Abnormal equipment wear or failures usually occur due to lubrication issues. Checking oil condition usually involves a time-consuming process of sending samples off to a lab, again involving costs and potential downtime. Using fluorescence spectroscopy, the Gastops concept technology can quickly measure critical factors of degradation of anti-oxidants (additives), the presence of fuel dilution, and coolant/water contamination and can do so in real time and on-site.

"We understand the obstacles our clients face in terms of scarcity of maintenance resources and increasing levels of maintenance required to ensure mission readiness of assets, whether aircraft or ships. We think OCCM can be a game changer in terms of how things are maintained and promote availability of equipment while also reducing the burden on maintenance resources"Brennan told CDR.

LOOKING AHEAD

Brennan West says the firm is now working with partners on the OCCM technology to achieve TRL-9 and to create new form factors for MetalSCAN to enable even simpler installation. The company is eager to bring their aviation proven solutions to the naval marine and land vehicle space.

West says while continual improvements are being developed with MetalSCAN, ChipCHECK and OCCM, they are working on broadening their solution portfolio with partners under an ITB (Industrial and Technological Benefits) agreement on advanced engine diagnostics using Gas Turbine performance data.

Using data from aircraft engines for 'near real time' evaluation of the health of those engines help to identify work scopes required to restore engines to proper operation. Through creation of an accurate simulation of an engine, data from an actual engine operation is collected and compared to the simulation enabling identification of the degradation modes present in the engine and establish maintenance needs to rectify the issues that are present.

West also told CDR, "We're developing and producing innovative equipment health management solutions. MetalSCAN, ChipCHECK, and OCCM all look at the oil wetted side of an engine, and the physics-based, data-informed modelling approach looks at the gas-path side of an engine. So not only can we evaluate the health and condition of oil wetted components, but we can also evaluate the health of components in the gas path; seal and blade tip clearances, surface coatings, flow path geometries isolate a given module within a gas turbine engine which is degrading performance and what maintenance is needed to rectify the issue".

He notes that while this innovative technology is primarily developed with aerospace in mind, it can also be applied to marine and land gas turbine engines. West adds that it is an exciting time to be a part of the Gastops team, as the company’s solution portfolio grows, partnerships within the naval marine and land vehicle markets expand, and end users continue to recognize the material availability gains that can achieved through use of Gastops CBM technologies.

Marc Montgomery is a Regular CDR Contributor