INDUSTRY PROFILE - IMT Defence

BY JAMES CARELESS

IMT Defence

100+ Years of Serving Canada and Its Allies

For more than 100 years, IMT Defence (part of the IMT Group of companies) has been supplying medium/high caliber projectiles (ammunition) to the Canadian army and its allies. Working at plants located in Port Colborne and Ingersoll, both in Ontario, IMT Defence has become an essential partner to these clients – so much so, that the company is now the Canadian Armed Forces’ primary source of medium/large calibre ammunition and a key supplier to the U.S. military.

For more than 100 years, IMT Defence (part of the IMT Group of companies) has been supplying medium/high caliber projectiles (ammunition) to the Canadian army and its allies. Working at plants located in Port Colborne and Ingersoll, both in Ontario, IMT Defence has become an essential partner to these clients – so much so, that the company is now the Canadian Armed Forces’ primary source of medium/large calibre ammunition and a key supplier to the U.S. military.

CDR’s Ottawa Bureau Chief, James Careless, recently spoke with IMT Defence President, Remo Assini, to learn more about the company and how it is faring in the current economic climate.

CDR: Is it accurate to say that IMT Defence is an absolutely essential ammunition supplier to Canada and the United States?

RA: It is. We are one of the few medium/large calibre projectile – the metal shells that hold the explosives – manufacturers in North America. In Canada, there is no one else that has our capability. This makes IMT Defence strategically vital to the Canadian government.

We make these projectiles from raw metal up to the point that they are ready to be loaded with energetic explosive materials, which are handled by other prime contractors or – in the case of the U.S. military – by their own loading facility. We start with the custom metal forging process in our Port Colborne plant, and then machine these projectiles to extremely tight tolerances at our Ingersoll facility. We also handle painting, assembly, and testing of this ammunition.

I should add that projectiles are not all that we produce at IMT Defence. We also manufacture vehicle components like drive shafts and leaf springs for suspension systems, plus articulating tow bars for the LAV (Light Armoured Vehicle) and the TAPV (Tactical Armoured Patrol Vehicle). We make those tow bars under license, and we also distribute the track shoes for Canada’s Leopard tanks.

STATE-OF-THE-ART MANUFACTURING

CDR: You manufacture and machine projectiles ranging in size from 25mm to 155mm for army, air and naval weaponry. Just how precise is your manufacturing process?

RA: It is very, very precise. The projectiles we manufacture can travel as far as 40 kilometres to reach their targets, which means that the shape, balance and finish of these shells have to be extremely accurate.

The weight also matters. It must be exactly what the customer has contracted for to ensure that the projectiles perform as expected on the battlefield. Most of all, the product quality has to be consistent and dependable.

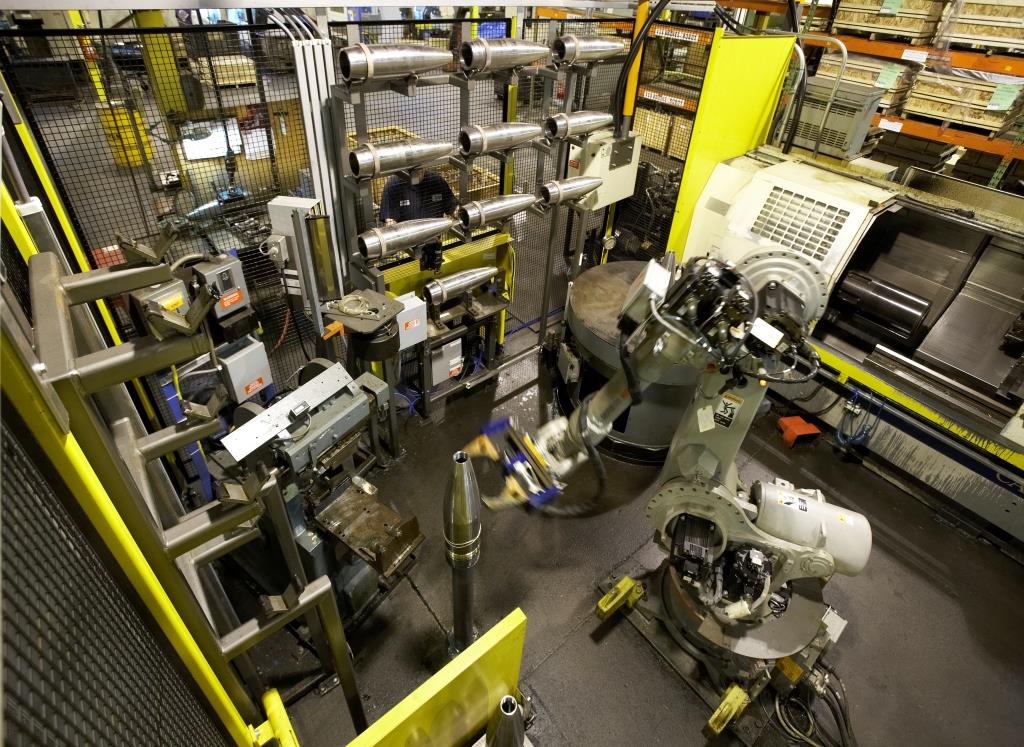

One way IMT Defence achieves this precision is through the use of computer-aided design (CAD) and computer numerical controlled (CNC) manufacturing machines/ robots. We have more than 20 robots in our projectile manufacturing process, performing a range of very high-tech processes.

We have invested heavily in these systems, plus process automation to ensure that IMT Defence is making the best quality projectiles possible. One that comes to mind is our production line for 40mm high velocity grenades, which are manufactured using high speed automated CNC machines.

CDR: How important is testing to maintaining the quality and consistency of IMT Defence’s projectiles?

RA: Testing is how we keep our promises to our clients. We perform ultrasonic, pressure, and other specialized tests and inspections – many of them automated – during the projectile production process to ensure that we are meeting our standards as an ISO 9001 registered facility. We also select a very small sample of the finished products for destructive testing, to see what kinds of stresses the products can stand up to and how they fail when they exceed specifications.

CDR: What value does IMT Defence’s focus on end-to-end quality provide to your customers?

RA: It gives the customer reassurance that we are meeting the high standards required for these products. And make no mistake: Consistent high standards matter when you are dealing with items such as explosive projectiles.

In the case of an artillery round, you've got a group of soldiers that are attending the gun as they fire the ammunition. They need to be confident that these projectiles are safe to handle. Precision also matters: When you are firing a shell at a target that is 40 kilometres away, they have to be sure that it will hit where they need it to. This is why total quality control from start to finish is central to what we do at IMT Defence.

COVID-19

CDR: How has the pandemic affected IMT Defence, and how have you coped with it?

RA: We're considered to be an ‘essential service’ and so we never did shut down. We’ve done our best to keep our people safe as they continue working.

At the beginning there were a lot of unknowns, issues and challenges that we had to work through. But as the months went by, we became quite the experts at doing the right things to protect our people. We’ve changed company policies to incorporate these changes, so that IMT Defence’s skilled workforce are always manufacturing products in a safe environment.

CDR: Speaking of skilled workers, IMT Group was actively advertising for new employees before the onset of COVID-19. Is this still the case?

RA: Yes, it is. We are still looking for new skilled hires.

Finding people has been a challenge, despite the fact unemployment is still at a high level. I’m not sure if this is a local issue or not. What I do know is that IMT Defence needs more people, which is why we’re hiring candidates with lesser skills and then spending more time training them in-house.

We don’t really mind doing this, since it allows us to focus on the kinds of people we want and then teach them the skills that they need. Still, the challenge lies in finding them. We’re just not getting the number of people applying for jobs right now that we usually do.

CDR: What future programs are on the horizon for IMT Defence?

RA: On the production side of our business, we are looking at new processes such as additive manufacturing –also known as 3D printing -- and the benefits it could to our operation. We are always seeking better ways to do what we do.

As for opportunities? IMT Defence is looking at the Canadian Surface Combatant naval procurement. There’s an ammunition requirement associated with this project that we would like to fulfill. We are also interested in the Ground Based Air Defence and Future Fighter procurements, both of which have substantial ammunition requirements.

CDR: Overall, are you optimistic about IMT Defence’s future?

RA: I am very optimistic. We've been on a steady growth curve for the last four or five years. We continue to add programs within Canada and the US with some very successful long-term contracts being signed recently. So IMT Defence is projecting healthy growth for the next few years, at the very least.

CDR: Thank you.

James Careless is CDR’s Ottawa Bureau Chief